CARBIOS Active: the biologic solution that makes plant-based plastic compostable even at ambient temperature!

This innovation, provided by Carbiolice, is designed for plastic applications and packaging, which, by their nature, cannot be recycled. Whether it’s too thin, too complex to recycle or soiled by food, 91% of plastic waste ends up being incinerated, landfilled, buried or dispersed in nature.

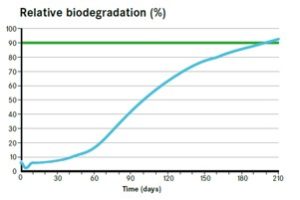

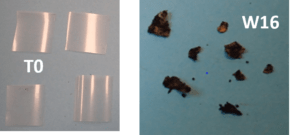

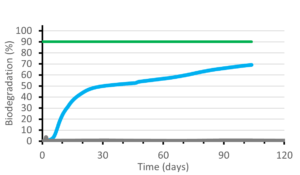

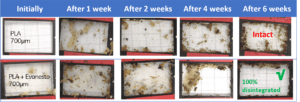

CARBIOS Active is an innovative and eco-responsible alternative that makes it possible to achieve zero waste. Biolastic containing CARBIOS Active can be collected with biowaste and will completely disintegrate and biodegrade in less than 8 weeks.

CARBIOS Active is the first biological solution allowing PLA rich-films to be certified “OK compost HOME”.

This technology contributes to the fight against plastic waste accumulation in the environment and becomes an effective lever for the deployement of a high-performance solution for sorting bio-waste at source.

CARBIOS Activereconciles plastic and environment, find out how!

How CARBIOS Active works to improve the bioplastic end of life?

CARBIOS Active is an encapsulated enzyme incorporated into flexible and rigid PLA packaging at a specific percentage, making it 100% compostable, even at room temperature.

Consequently, it completely disintegrates and biodegrades, yielding compost without any residue or toxicity, providing a high-quality return to the soil.

-

Flexible films

-

Trays

-

Coffee capsules and tea bags

-

E-commerce packaging (bubble wrap, polybags, etc.)

-

Agricultural applications (mulching film, pots, etc.)

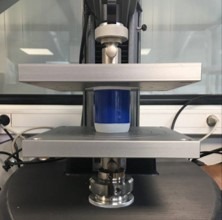

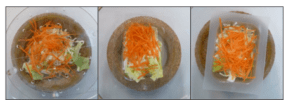

In-house home composting test

In-house home composting test